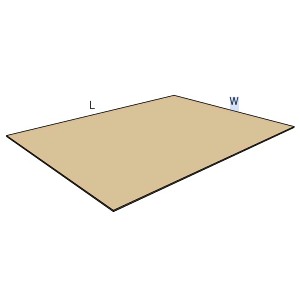

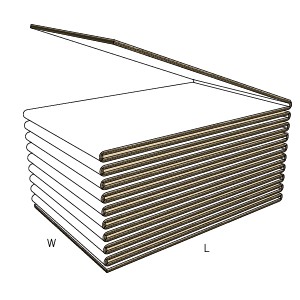

Fefco 0110 Corrugated Cardboard Flat Sheet

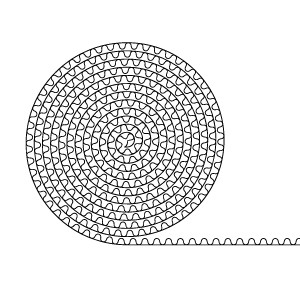

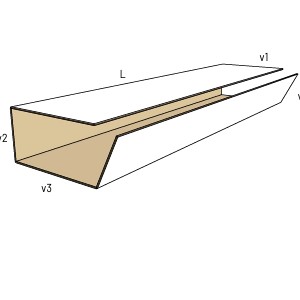

Fefco 0111 Single Crimped Cardboard

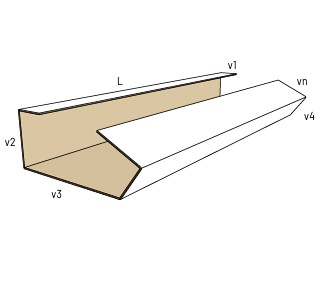

Fefco 0112 Double Crimped Cardboard

Fefco 0113 Three-Crimped Cardboard

Fefco 0119 Four-Crimped Cardboard

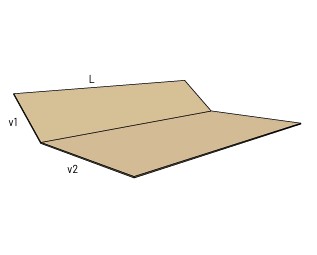

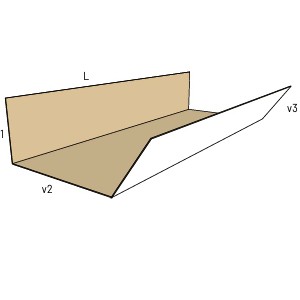

Fefco 0130 Folding Cardboard

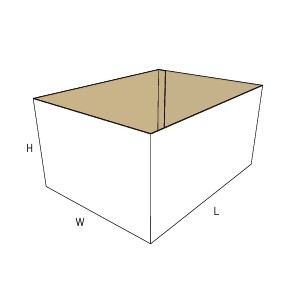

Fefco 0200 Open Top Box

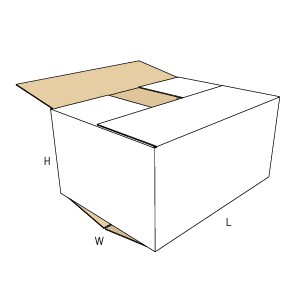

Fefco 0201 Standart ABox

All the lids of the standard box are the same size. Their outer covers converge in the middle of the box. The distance between the inner Decals varies depending on the size - to - size ratio of the box. They become the packaging of many products. If it is desired to better protect the product on the bases, a piece suitable for the size is placed in the space left between the Decals. This method is especially used to eliminate the step difference that occurs at the bottom of the box in boxes that are produced from multiple waves and where many products are packaged.In such cases, the less economical box 204 can also be used.

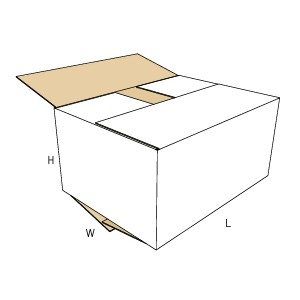

Fefco 0202 Double Side Long Lid Box

The difference from the standard box is that all cover lengths are kept long in the specified dimensions and the outer covers are superimposed. This solution, which is another way to make the Decking space between the covers economical in terms of production and use, is usually used as packaging of heavy products. Otherwise, it creates a problem in the stack because the box base will not come parallel to the ground. The covers of these types are usually closed with wire stitching.

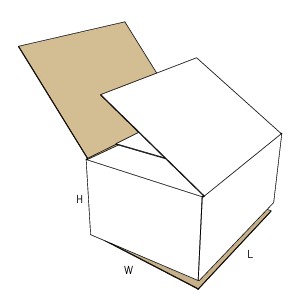

FEFCO 0203 Full Lid Box

This type, in which the box outer covers are exactly superimposed, is resistant to collapse. The boxes, which are usually the narrowest in size and stacked on the side face, are resistant to stacking due to the cardboard layer formed at the beginning.

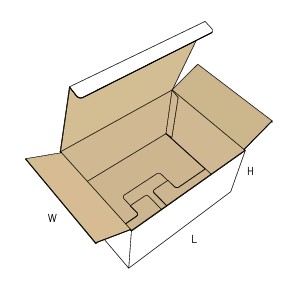

FEFCO 0215 Switch-Based Box

This box, which is one of the molded box types, is usually considered as consumer packaging due to its lower and upper lids, which are locked when closed with a certain sequence without requiring tape. The splicing part is usually performed as gluing in the company that makes the box production.

FEFCO 0301 Telescopic Box

The boxes, which are called molded or produced as a standard pan, are shipped flat. After installation, the corners are glued or sewn by the user company. They are widely used in cut flower packaging processes in our country.

FEFCO 0320 Telescopic Box

It is formed by passing two 0200 coded boxes with a lid on one side onto each other with their mouths facing each other. Usually the inner and outer box are made of different corrugated cardboard. The presence of a double layer of cardboard thickness on the side walls makes the box durable. Especially in these types used as citrus packaging, since the collapse value of the box decreases due to external factors such as climatic conditions, waiting in the stack, shipment, the inner parcels are produced moisture-resistant using double wave, even various auxiliary materials on some faces. The outer boxes, on the other hand, are usually produced with stunning prints using white or marbled papers. In particular, the loss of surface crush value caused by pressures on large surfaces decreases in this type of box.

FEFCO 0350 - 0351 Bulk Box

They are used in the packaging of granular and powdered products. This box, which is shaped with octagonal pans passed on the bottom and top of octagonal tube-shaped side walls, can carry very large loads due to its geometric form. It is moved with the pallet, fastened to the pallet by strapping. When it comes to powdered products, a plastic bag with a large bellows is used inside.

FEFCO 0409 One-Piece Telescopic Box

This box, which is usually sealed in automatic filling machines, is multi-purpose. It packages many products from durable consumer goods to meat. It is resistant to stacking on top of each other.

FEFCO 0422 Folding Interlocking Sheet

This pan box, which is one of the molded box types, is an extremely durable package when used telescopically, which is folded by hand by the user in cases where automatic filling is not in question, as it is used closed together with other types. Usually used in bottles, jars, etc. pan box used for products; cherry, etc. by adding ventilation and handle places. it is used as the packaging of fruits.

FEFCO 0451 Four Point Gluing Pan Box

Pans produced by mold, shipped flat after the four corners are glued, are boxes. They are also used as covers by combining with other types. They are very easy to install and are widely used as packaging for durable consumer goods and foodstuffs.

FEFCO 0460 Automatic Filling Pan Box

This pan box, which is one of the molded box types, is used for packaging products such as beverages, soft drinks. It is an economical type, the use of which is quite common.

FEFCO 0713 Collapse Based Box

These are boxes produced with a mold, splicing and base bonding are made and shipped flat. They are usually produced with single-wave cardboard. They are used as consumer packaging. Before use, the bases of the box are automatically installed by pushing the diagonal corners towards the middle. They do not require additional materials for closure. Oct. They are an indispensable type of offset printed boxes and are used in the packaging of glass and sensitive products such as these.

FEFCO 0900 Deca Carton

It is the part placed to fill the gap left between the lids of the most Decked corrugated cardboard boxes.

FEFCO 0901 - 0902 - 0903 Intermediate Decking Carton

Corrugated cardboard are flat sheets that divide the box horizontally and vertically.

FEFCO 0904 Environmental Reinforcement Carton

Corrugated cardboard are rilled parts in accordance with the internal dimensions of the box in order to strengthen the side surfaces of the box and to provide stacking strength. The grooves of these reinforcements are always parallel to the slotter rills.

FEFCO 0933 Separator

It is a separating material used in corrugated cardboard boxes, produced in as many eyes as desired. It ensures that the products that need to be packaged individually are placed safely in the same packaging by taking them into protective eyes.